Basic consideration of Cleanroom

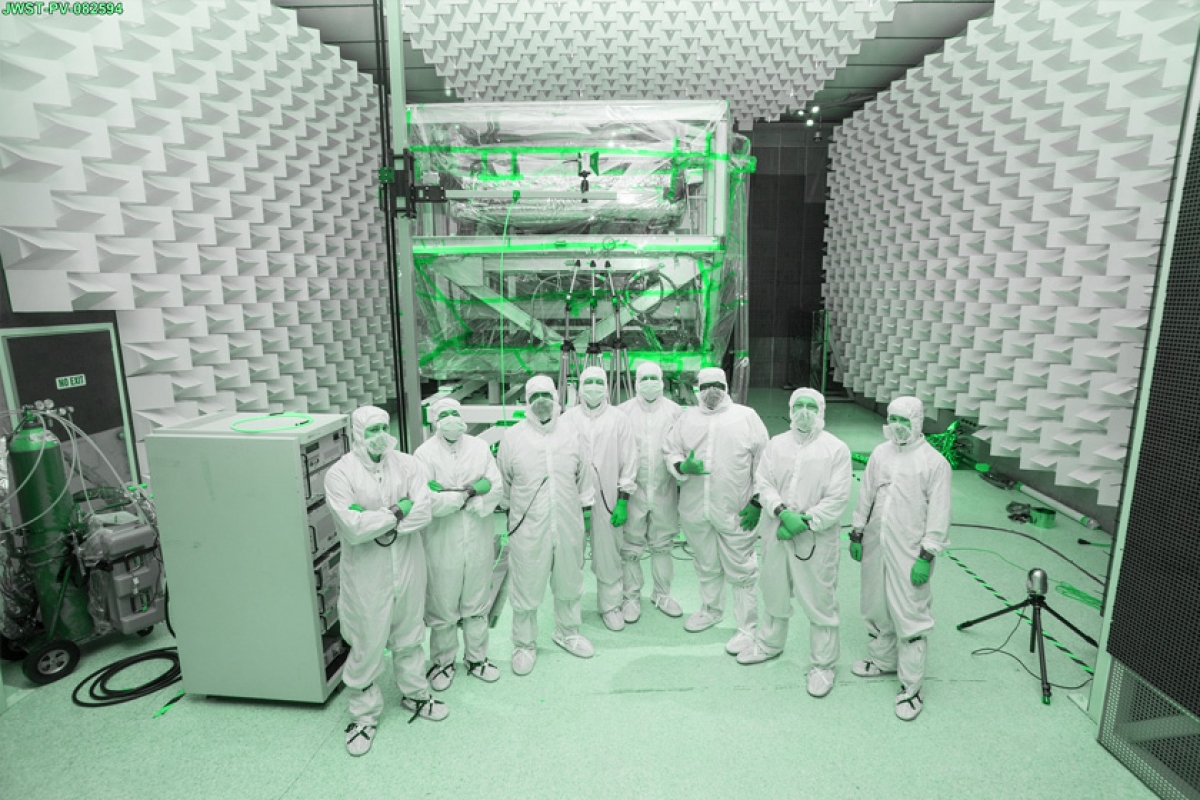

Environment Conditions

- The relocation of staffs, materials and manufacture machines is appropriate

- Clearly Classified different cleanliness class for different area such as production area, maintenance area and corridor

- The temperature and humidity have control by 24 hours automotive monitoring system and usage patterns

- The smoothly of pipeline, moving lines in facility supply system

- Cleanroom level design assessment

- The convenience of secondary piping hock-up construction

- The convenience of overall system maintenance

Economic Conditions

- The reasonable of factory system supply and equipment procurement.

- The life cycle of the facility supply system and the equipment operation

- The initial set-up cost

- Operation cost

Reliability & Stability

- The stability of factory supply system

- The stability of the operation of process equipment

- The reliability of all raw materials

- The high productivity feasibility assessment

- The back-up equipment evaluation & selection

- Storage system design

Safety and environment protection requirements

- Safety Consideration on cleanroom operators, the evacuation route direction is clearly indicated

- Classification and prevention of noise, vibration, acid, exhaust, drainage etc

- Marked and suspension position layout

- The fire system such as smoke and spray smoke etc

- The design and installation for emergency lighting, shower and eyewash system

- Established the poison gas, waste gas and waste water system

- Established the emergency contact networks

- The establish and implementation of emergency response procedures

- The establish of environmental protection facilities such as poison gas and waste water treatment

- Process waste reduction

- Recycling, renewable, remanufacture → reuse

Flexible expansion capabilities

- Space reserved

- The allowance capacity of factory supply

- The convenience of the compartment removable

- Production line layout

- The design and planning for non-stop expansion

- The interaction between production fab and support area

- The design of the supply line expansion margin considerations

- Expansion construction isolation

Operating Condition

- Availability of back-up system

- Establish emergency stop for

- Door interval lock between cleanroom area and contaminated area

- Arrangement for shock proof and sound insulation works

- The protection for instant power restoration

- Establish energy saving countermeasures

- Easy to maintenance

- Establish reliability monitoring system

Personal comfort consideration

- The main assets of the company

- Humane management

- The staffs moving line in and out

- The facilities required on daily life

Resources & Articles

CLIN ® "Resources" page is for individuals/companies seeking information on cleanrooms and controlled environments. Find Cleanroom News, Discussion Forums, Cleanroom Cleaning Recommendations, Cleanroom Terminology, Cleanroom Directory, and more.

Content Disclaimer

Information are contributed by/from different websites and all credit goes to its respective owners/writers/websites/companies and etc, and while we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Through this website you are able to link to other websites which are not under the control of respective owners/writers/websites/companies and etc. We have no control over the nature, content and availability of those sites. The inclusion of any links does not necessarily imply a recommendation or endorse the views expressed within them.

Every effort is made to keep the website up and running smoothly. However, CLIN ® takes no responsibility for, and will not be liable for, the website being temporarily unavailable due to technical issues beyond our control.