Selecting the Right Color Temperature

Color temperature is the hue of light emitted by a source, measured in Kelvin (K). It ranges from warm tones, or lower Kelvin values, to cooler tones, or higher Kelvin values. Understanding color temperature is essential for worker comfort and task performance in cleanroom environments, where precision, hygiene, and visual accuracy are critical.

A suitable color temperature for cleanroom lighting typically ranges between 4000K and 5000K, which provides neutral to cool white light. This range offers optimal brightness and contrast without causing eye strain or color distortion. Cooler color temperatures are ideal when cleanliness, precision, and high visual acuity are required, such as in healthcare or high-tech manufacturing environments.

Lumens Explained

Lumens measure the total amount of visible light emitted by a source. In short, the brighter the light, the higher the lumens. Unlike watts, which measure a light source’s energy consumption, lumens focus solely on brightness. This is a more accurate metric for selecting cleanroom lighting, where specific illumination levels are required to avoid shadows, minimize eye strain, and provide consistent visibility.

Why Lumens Matter in Cleanroom Lighting

Cleanrooms require a certain brightness level to support the detailed work involved in various processes. Insufficient lighting can lead to errors and fatigue, while excessive brightness can cause glare and discomfort. Calculating the required lumens for your cleanroom ensures you achieve the optimal lighting balance.

Calculating Lumen Requirements

To calculate the appropriate number of lumens for a cleanroom, you’ll need to consider the following factors:

- Room size: Larger spaces need more lumens to ensure uniform light distribution.

- Ceiling height: Higher ceilings require brighter lights to compensate for the distance between the light source and

- the work surface.

- Task complexity: Tasks that demand high precision may need more lumens to support clear visibility, especially when dealing with small components or sensitive processes.

As a general guideline, aim for 300-500 lumens per square meter. For highly detailed work, you may need up to 1000 lumens per square meter to ensure adequate brightness and clarity.

Factors for Consideration

When selecting cleanroom lighting, it’s essential to understand the space’s environmental conditions and cleanliness requirements. Two critical factors are the environmental impact and ensuring lighting matches the cleanroom class.

Environmental Factors

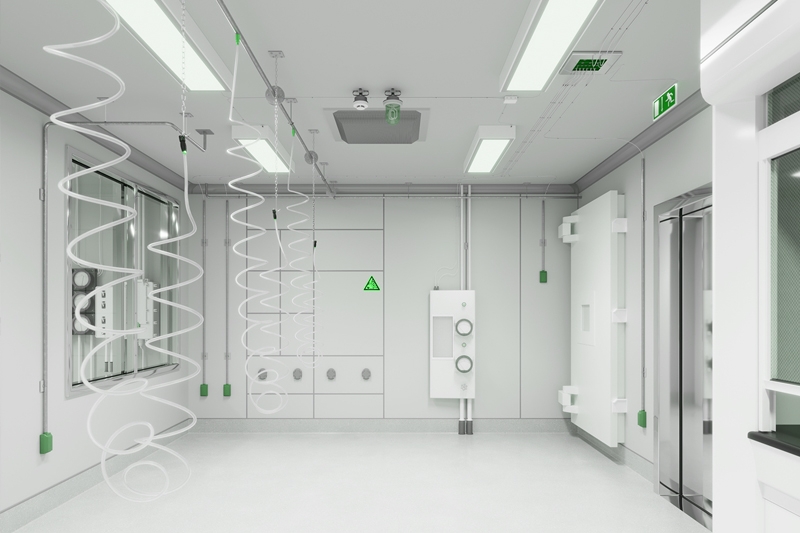

Cleanroom environments have stringent regulations for airborne particles, temperature, and humidity. The lighting selected for these spaces must meet illumination standards and be compatible with these environmental conditions.

Heat Emission

Lighting that generates excessive heat can impact the air quality and increase the burden on the HVAC system. Selecting low-heat-emitting lights, such as LEDs, is crucial to avoid temperature fluctuations that could disrupt the cleanroom environment.

Dust and Particle Emission

Traditional lighting systems may contain materials like mercury or fragile parts that can break or degrade over time, increasing the risk of particle contamination. Cleanroom lighting must be sealed and designed to prevent the release of any particles into the controlled environment.

Energy Efficiency

Maintaining strict environmental controls in a clean environment is energy-intensive. Temperature and humidity control, air filtration and purification, positive pressure, and HVAC systems lead to high energy use in cleanrooms. Energy-efficient lighting solutions help reduce operational costs without sacrificing lighting quality. They also contribute to better sustainability practices by minimizing energy consumption.

Matching Requirements to Cleanroom Class

Cleanrooms are classified based on the allowed concentration of airborne particles, ranging from ISO Class 1 to ISO Class 9. The lighting requirements must align with the cleanliness class of the cleanroom, as lighting fixtures can impact both the air cleanliness and visibility.

ISO Class 1–3 Cleanrooms: These environments, often used in semiconductor manufacturing or biotechnology, demand highly specialized lighting that emits minimal heat and particles.

ISO Class 4–6 Cleanrooms: This class range is typically used for pharmaceuticals or medical device manufacturing and requires high-performance lighting to maintain consistent air quality. Lighting fixtures must also be designed to be easy to clean and resistant to chemical exposure.

ISO Class 7–9 Cleanrooms: These spaces typically have looser particle restrictions but require lighting that supports visibility and reduces contamination risks.

By considering these environmental factors and matching lighting solutions to the cleanroom class, you can ensure a clean, safe, and productive working environment. PAC’s extensive experience in cleanroom environments and a deep understanding of cleanroom classification standards allow us to deliver lighting solutions that meet even the most stringent requirements.